Spring Calculator

Spring Calculator Spring Calculator

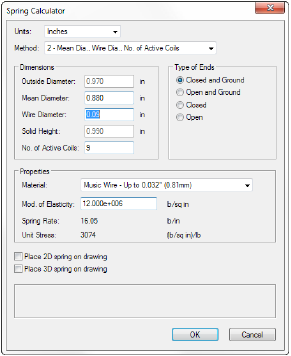

Spring CalculatorThe spring calculator can determine spring rates and unit stresses of round wire helical coil compression springs with known parameters. It can also be used to design a spring knowing the working values. This example is based on the following compression spring with closed and ground ends of music wire.

To calculate spring rate and unit stress:

Determine the required spring rate based on the deflection at a load divided by the difference in the working length and the free length. For this example, the desired spring rate equals 28.8 lb/in (36 lb/1.25 in = 28.8 lb/in).

Select the Spring Calculator command from the appropriate menu:

● Architect workspace: AEC > Machine Design > Spring Calculator

● Landmark workspace: Landmark > Machine Design > Spring Calculator

● Spotlight workspace: Spotlight > Machine Design > Spring Calculator

The Spring Calculator dialog box opens.

As shown in the above dialog box, select 1 - Outside Dia., Wire Dia., Solid Height from the Method list. After entering the known values, calculate a spring rate close to the desired value by trying several standard wire diameter values. Adjust the material in the Material list to fit the wire diameter used. Here, a wire diameter of .090” gives a spring rate of 8.94 lb/in.

In the Method list, select 2 - Mean Dia., Wire Dia., No. of Active Coils.

As shown in this dialog box, vary the wire diameter and number of active coils to get a spring rate close to the required spring rate. A wire diameter of .095” and 11 active coils gives a spring rate of 16.3 lb/in, but the solid height is 1.24”, which is too high. A wire diameter of .090” and 9 active coils, however, gives a spring rate of 16.1 lb/in, and a solid height of .990”, which is within acceptable limits.

Finally, check the stresses applied to the spring to verify that they are within acceptable limits. With a unit stress of 3074 (lb/sq in)/lb, multiply by 36 to obtain 110,663 lb/sq in. With a solid height of .990”, the stress will be:

(2.500-0.900)in x 16.1 lb/in x 3074 (lb/sq in)/lb = 79,200 lb/sq in

This value is below the safe working stress of 111,000 lb/sq in for this material and wire size.